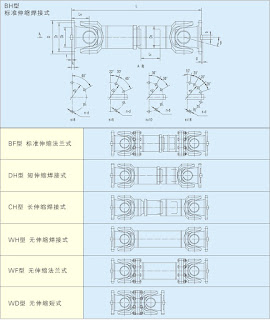

A-Catalog Cards D-Top Connections

B-Wall Joints E-Angle Connection

C-Bottom Connections F-Doors Joints

Constructional system of partitions and linings characterizes by almost complete prefabrication of elements and mounting profiles. It ensures easy and fast installation, and accommodations of high standard. Accommodations designed in this system meet the requirements of fire protection of all classes and acoustic insulation.

Beside basic partitions and linings we supply also partitions and linings for wet areas.

CONSTRUCTION

The “sandwich” panels used in construction are made from galvanized steel sheets coated with decorative PVC foil. Between steel sheets there is thermal and acoustic core made of mineral wool. Lengthwise edges of board are fastened with a connector and are shaped in such a way that they form “own fastener”. These are also known as progressive style panels. We can also supply “C” clip panels, which are a non‐progressive system and allows for easy assembly and dismounting without disturbing adjacent panels. The completeness of the system lies in the fact that the producer offers bottom and top profiles, multi‐functional corner profiles, which make various joints between walls and wall/ceilings possible. In addition we can supply lining doors, cable casings, window framings, cases for the extinguishers.

FIRE RESISTANCE

-Basic materials are classified as non‐combustible.

-Finishing materials (decorative coatings) meet the requirements of international standard in scope of low flame‐spread characteristics. All materials are non‐toxic.

-Presented wall structures passed international fire test according to SOLAS‐1974 Convection with

amendments and comply with relevant requirements.

-Wall structure is approved as B0 and B15 by different Classification Societies and National Authorities.

-Certificates of approvals, materials and approved drawings of mounting joints are submitted on request.

MOUNTING

Mounting of wall panels must be carried out in accordance with a design. Before starting mounting of walls, the places of fixing bottom and top channels shall be marked on the steel deck. Bottom, top channels and fasteners or curtain plates shall be welded to the steel deck. Partition and lining boards are placed in bottom and top channels, which create a self‐supporting construction of walls. Various corner and wall profiles are used for corner joints.

Completing wall structure panels should be mounted in the last sequence of outfitting. The mounting of boards located near doors is done after fixing doors by means of “Omega” profile or two guiding profiles. All additional casing such as: pilers, ducts shall be made of cut‐off panels. All joints of these panels shall be masked by standard or untypical finishing profiles. Visible surfaces of boards and profiles are protected by peel‐off foil during production and assembly. Lukewarm water and soap or ordinary detergent usually removes dirty stains. Never use any abrasive means or scouring powder.